Published 29/04/2020

Moa Point wastewater pipe rehabilitation

Work has begun on lining a section of wastewater pipe near Moa Point Wastewater Treatment Plant with a new, more resilient lining to maintain reliability.

The project was fast-tracked after an inspection of a section of the main pipe which carries Wellington’s wastewater to Moa Point for treatment —known as an interceptor—revealed internal corrosion exposing reinforcement bars.

The inspection was part of Wellington Water’s standard ongoing review of critical assets that we make to understand the condition of our assets and prevent failures that impact people and the environment.

A CCTV view of the interceptor’s interior revealed corrosion.

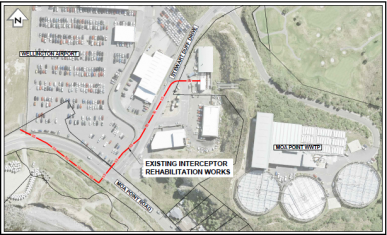

Most of the section of the interceptor to be rehabilitated is under Moa Point Road and Stewart Duff Drive, but excavation of the vegetated bund on the seaward side of Moa Point Road is also required to expose a buried access point.

The sections of the interceptor to be rehabilitated are shown in red.

The work is being undertaken for Wellington Water by Interflow Pty Limited who are relining the existing pipes in a trenchless operation, meaning disruption above ground is minimal and existing underground services don’t need to be negotiated. It’s also a durable long-term solution, using the proven material of PVC—the same as a normal pipe.

Wellington Water’s team include Interflow’s Project Manager Saadia Ali (left) EN Ramsbottom’s Project Leader Michelle Hoffmann (centre) and Graduate Civil Engineer Kirstin Woods (right) from Stantec.

Before the main section of the interceptor can be relined it must be over pumped, which means the wastewater flowing through the interceptor must be diverted to allow for the relining machine to operate within the pipe. This work is being undertaken on behalf of Interflow by local contractor EN Ramsbottom.

The picture below shows the temporary pipes that will divert wastewater from above and below the sections of pipe to be relined. The steel boxes house diesel pumps

Michelle Hoffmann, project leader for sub-contractor EN Ramsbottom, said the diversion pipes are in place. ‘We have a contingency plan if the interceptor fails. So that’s good. Now we’re trialling and fine-tuning the pumping before Interflow put in the new lining.’

Michelle said they had to act very quickly to get everything on site before the lock down took effect, and that while the ongoing working environment has its challenges, there is an upside.

‘With the airport being so quiet, our work with large machinery hasn’t been restricted between 1 and 6 am. And we have not had to contend with vehicles parking in the long-term car park, where we have set up our pumps. Silver linings, you could say.’