Seaview Wastewater Treatment Plant Upgrades

We’re upgrading the Seaview Wastewater Treatment Plant on behalf of Hutt City Council and Upper Hutt City Council to reduce odour and discharges of untreated or partially treated wastewater and future-proof the plant, starting with odour improvement.

If you have any questions about this work, please contact:

Wellington Water, 04 912 4400

Latest Updates

September 2025

Dryer Replacement Project

Now that Downer have been appointed as design and build contractor for the Dryer Replacement Project, the team are fully focused on completing the concept design and procurement of the main plant and equipment. This is a complex and detailed process, with significant investigation needed to make sure the new dryers are designed specifically for the community’s requirements. We anticipate that construction will have commenced by May next year.

For example, not all sludge is the same. The team had to test the specific sludge that moves through the Seaview Plant, to better understand its qualities. This information is vital to make sure that the dryer is designed in the right way, so it can dry the sludge efficiently. This involved sending a sample of the sludge all the way to Germany for testing by an equipment supplier.

We’ll share more information on the road ahead as we work towards making the new dryer facility available for use in December 2027.

Odour Control Project

Stage 2 of the Odour Control Project has gotten off to a strong start, with a series of brief shutdowns to the Milliscreen room in August and early September now completed. This was part of our work to replace the existing ducting and fans, to reduce odour escaping from the equipment into the building and then to outside.

Construction continues onsite with the completion of the Milliscreen ducting due early September. Construction has also started for the Milliscreen Building Air Treatment Unit with the slab being poured this week. In the following month ducting for this system will be installed to take air from the Milliscreen building to the new air odour treatment unit. Once commissioned this will make the working environment for the treatment plant operators safer and reduce the amount of untreated air from the Milliscreen building being released.

New odour fans for the Milliscreen ducting and Biofilters are due to arrive on site in late September. The installation of these will require several odour system shutdowns which may increase the risk of odour for short periods. We’ll share information about these shutdowns closer to the time.

The Seaview Wastewater Treatment Plant is aging. Much of the plant’s equipment and parts are nearing the end of their service life, which means it is more prone to service interruptions and needs more maintenance. Find more information about the plant’s performance and resource consents here

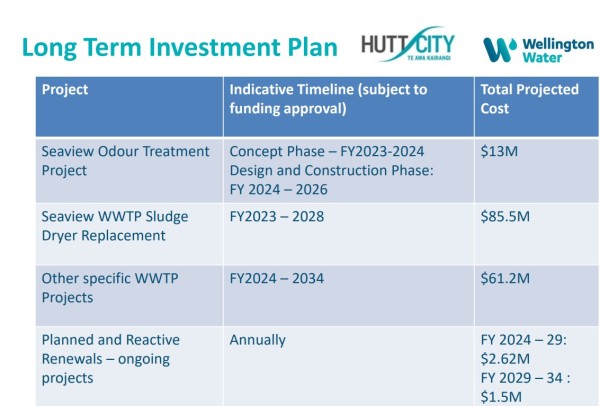

A multi-million-dollar programme of work is planned over the next six to 10 years to renew and upgrade equipment at the plant to improve its operation, subject to funding being confirmed. The current plan includes:

-

Odour treatment renewal project (2024-2026)

-

Sludge dryer replacement (2024 - 2028)

-

Ultra-violet (UV) disinfection equipment renewal (2024 - 2026)

-

Sludge pumps, aeration control system and aeration blowers (2024 - 2028)

-

Clarifier ( 2026- 2028)

This work will contribute to reducing odour and discharges of untreated or partially treated wastewater, increasing capacity to handle population growth, and improving efficiency.

There is no quick fix, but Wellington Water is committed to short- and medium-term interventions to effectively manage operations of the treatment plant.

More detail on each area will be provided as planning progresses. Wellington Water is also considering options for reducing overflows to the Waiwhetū Stream and replacing the Main Outfall Pipeline.

Project background

Odour Control Project

The objective of the odour treatment renewal project is to improve the management of odour to ensure the plant is a safe environment and is operating within its resource consent.

We’re aware odour continues to be a problem, based on community feedback and our own independent scouting.

In the short term, we are prioritising areas for action that will result in capturing more odourous air from the milliscreening process and ensuring that the biofilter system is working effectively to remove odours from this air.

In the medium term, we are assessing options to improve odour management from the sludge dryer area, noting the dryer is due for replacement.

As well as replacing equipment, we’ll continue with maintenance and operational activity that we expect to contribute to reducing odour.

Dryer Project

The Seaview Dryer is coming to the end of its life, and requires replacement to continue servicing the approximately 155,000 residents of the Hutt Valley.

It is an integral part of the wastewater treatment plant, drying out the sludge (a by-product of the wastewater treatment process) so there is less volume to transport and dispose of at the Silverstream Landfill.

The Seaview Wastewater Treatment Plant uses a biological process to treat wastewater, one which is carefully monitored and managed around the clock to keep it healthy and balanced. This both helps the process work as it should, and reduces the risk of odour. The dryer has a key role to play in this process, and when it is compromised the consequences can be significant.

The sludge dryer is prone to breakdown and for complicated repairs could be offline for periods that require dewatered sludge to be trucked to Silverstream, which poses a significant risk to the biological process and an immediate odour risk due to the unloading of odorous wet sludge.

To address these issues, a replacement of the current sludge dryer was proposed and approved, and as of August 2025 a contractor has been appointed, and they have entered concept design. The new dryer will have multiple operational benefits and lower carbon emissions. One of the key benefits of the design of the new dryer facility, is that it includes two dryers. This means that there is a level of redundancy in-built. If maintenance work is required on one, the other can continue drying sludge.

The replacement will increase treatment plant resilience, reduce odour emissions and is needed to meet the Hutt Valley’s future growth.

FAQs

Is the plant meeting resource consent standards?

We are working hard to improve the current performance of the plant and the way we operate. Our focus is to meet the required standards and be compliant with the resource consents. The plant is aging, much of the equipment and parts are nearing the end of their service life, which means the plant is more prone to service interruptions and needs more maintenance.

Why are there no covers on the aeration or clarifier tanks at the Seaview plant?

Seaview’s aeration tanks do not pose a significant odour risk when they are operating according to design, as we are actively blowing air into a mixture of suspended aerobic microorganisms. The clarifier tanks which follow the aeration tanks also have a low odour risk. In the event of a breakdown in upstream treatment processes or a power failure, odour from the aeration tanks is possible. This risk is better addressed by ensuring we have effective equipment and systems, than by covering the tank. It is not common practice to cover tanks here or overseas, and not practicable at Seaview given the plant’s design.

Why are the treatment plants at Hastings, Gisborne and Napier totally covered?

Those plants use a different treatment technology and are constructed differently to the Seaview plant. It’s a bit like comparing diesel with petrol systems. The Hastings, Gisborne and Napier plants use trickling filter tanks and spray the wastewater over an open tank filled with algae that grows on plastic media. This does not happen at Seaview.

Why didn’t you replace the biofilter plenum (air distribution system) in December, when replacing the biofilter media??

During the works in December 2023 and following a condition inspection, it was discovered that the ‘plenum’ [biofilter structure] had degraded and should be replaced. It was necessary to proceed with the biofilter media replacement, as undertaking this additional work would delay the immediate objective of improving odour levels. Inspection of the plenum was only possible after we started removing the old biofilter media.

It was in the media that the work to replace the biofilter should have started in 2021, why the delay?

The biofilter media replacement was never programmed to be replaced in 2021. This work started in November 2023 after condition assessment and lab testing of bark composition, and the availability of a specialist contractor. The replacement was completed ahead of schedule in December 2023.

Is the biofilter media replacement making a difference?

While the new biofilter media is establishing well, there are ongoing issues with odour levels. Replacement of the biofilter media is only one part of the solution. We are continuing independent odour scouting, as well as monitoring complaints from the public, as we continue to work on other issues contributing to odour.

What upgrades do you have planned, how much will it cost?

We are prioritising improvements in three key areas we know are causing significant odour issues: the biofilter system, the milliscreening building and the sludge drying building. Hutt City Council has budgeted $13 million for these works.

Is the odour issue ever going to be fixed?

Wellington Water and Hutt City Council are committed to resolving the issue, though this is not an overnight fix, and it will take time. We acknowledge this is concerning, frustrating, and upsetting for everyone given it has been a long-term issue that has got worse in recent years.

Are there any health implications with plant associated odour?

When odour levels are strong and unpleasant, it can make some people feel ill. We are not aware of any health implications (bacteria that can be inhaled) and are following standard health and safety guidelines with the maintenance works we are doing at the treatment plant.

Te Whatu Ora - Health New Zealand has done an assessment on the use of the deodoriser at the Seaview Wastewater Treatment Plant. Please find the statement and more information here

Given the projected long-term investment, is the plant's current design under review?

We have concluded the design of the plant remains appropriate but much of the equipment needs renewing and upgrading, because the plant is aging, and equipment has deteriorated more quickly than expected.

We have also considered projected population growth and the standards we are required to meet by current resource consents.

The odour treatment renewal project is the first workstream in this long-term plan, followed by the sludge dryer replacement. There are other proposed upgrades for the UV system, sludge pumps, aeration control and clarifier. In addition, there is ongoing planned maintenance such as the milliscreen replacement, and reactive renewals (replacing smaller items that fail).

There is no quick fix, but Wellington Water is committed to upgrading the plant so we can continue to protect the health of people and the environment, while catering for population growth.

What odour neutraliser spray is used at the plant?

Odour Neutraliser Plus (SCD 1100)

For more information about the odour control product being used at the Seaview Wastewater Treatment Plant > Odour Neutraliser Plus Assessment

About the odour treatment renewal project

We’re investing $13 million in work to improve systems to capture and remove odours at the Seaview Wastewater Treatment Plant to avoid odours reaching the community.

The objective of the odour treatment renewal project is to improve the management of odour to ensure the plant is a safe environment and is operating within its resource consent.

We’re aware odour continues to be a problem, based on community feedback and our own independent scouting.

In the short term, we are prioritising areas for action that will result in capturing more odourous air from the milliscreening process and ensuring that the biofilter system is working effectively to remove odours from this air.

In the medium term, we are assessing options to improve odour management from the sludge dryer area, noting the dryer is due for replacement.

As well as replacing equipment, we’ll continue with maintenance and operational activity that we expect to contribute to reducing odour.

Treating odour

The Seaview Wastewater Treatment Plant uses physical and biological processes that harness the action of bacteria and other microorganisms to clean the wastewater. One of the side-effects of this process can be odour. The plant is designed to treat odours.

Odourous air is pumped to the biofilter, where is passes through a bed of media (mainly bark, gravel and limestone chip) containing microbes that break down the odour-causing compounds.

The Seaview plant also uses an odour neutraliser, which sprays a safe chemical mix into the air to neutralise odours.

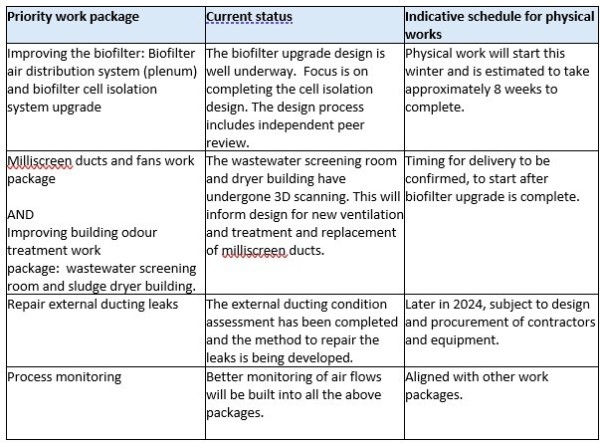

Priority work

Improving the biofilter

When the biofilter media was replaced in December 2023, a comprehensive mechanical and structural condition assessment was undertaken. It became evident that:

-

The air distribution system (plenum) in all six biofilter cells needs replacing.

-

The biofilter cell isolation system needs redesign and upgrading to isolate each of the six cells individually, this would avoid odour discharge to the environment during routine maintenance events.

This work was completed in October 2024.

Capturing odours from the milliscreens

The wastewater screening room houses 10 inlet screens. These remove large solids from wastewater as it enters the plant. Find out more about the process here. This is typically the most odourous part of any wastewater treatment facility. The screens and channels are covered, with multiple ducts connected to the odour extraction system. This allows odourous air to be extracted with a fan and sent to the biofilter for treatment.

We know that there is an issue with the ducting from the milliscreens which is allowing odour to escape from the equipment into the building and then to outside. These ducts will be replaced to restore capacity.

We also plan to replace the fans that help extract odour around the plant.

Capturing and treating building air

While ducts capture air from the covered screens and channels, other air in the wastewater screening room vents directly to outside. We will upgrade the ventilation system to capture the building air for treatment before it is released. This is likely to involve installing new carbon air scrubbers in this building, subject to detailed design and planning being completed.

We are also looking at options for improving management of air from the sludge dryer building.

Repair external ducting

We know that some of the odour ducts running outside the buildings (external ducts) have leaks. This means that some of the captured odour escapes, and it also reduces the effectiveness of the fans in drawing out the odour from the different process areas. We have completed condition assessments on the external ducting and are planning how to repair leaks.

Process monitoring

Better monitoring of air flows will be built into all the above packages.

Phase 2

The second phase includes two work packages; sludge dryer air treatment and further external ducting, as required. Both of these would require an assessment of the effectiveness of the first phase in reducing odour issues. The sludge dryer air treatment also needs to be considered alongside the work to replace the sludge dryer.

Kia ora koutou,

Welcome to the November Seaview Wastewater Treatment Plant Newsletter.

In this edition, you’ll find an update on:

-

-

general plant operations and maintenance

-

an upcoming dryer shutdown

-

dryer replacement and UV projects

-

the odour control project and upcoming works

-

resources from the community meeting, and

-

odour monitors.

-

Plant Operations and Maintenance: 1/10 - 31/10

Throughout October, Dissolved Oxygen and Mixed Liquor levels remained within target levels. Check out the graphs below for trends over time.

Seaview’s effluent compliance is measured as a 90-day geometric mean and a 90-day 80th percentile. This means that in any 90-day period, not more than 18 days are permitted to be over specific set limits for things like suspended solids or faecal coliforms. Effluent quality compliance for suspended solids and BOD was maintained over the month. We have remained out of compliance for faecal coliforms since late September. Our compliance is consistently monitored, and a summary of the full month’s compliance is published around the third week of the following month, here.

Notified works for October included:

-

-

Seed silo maintenance

-

Effluent pump maintenance (no risk of odour)

-

We received no odour complaints, and no assessments of objectionable and offensive odour.

Upcoming Dryer Maintenance and Shutdown

Maintenance is required on the dryer drum, which is planned for Monday 1 to Saturday 6 December. This includes 2 days of contingency. This will bring forward some of the work planned for early 2026.

To maintain the health and balance of the plant during these shutdowns, and reduce the risk of any ongoing odour issues, sludge will be trucked to Silverstream Landfill. This may result in a temporary increased risk of odour due to the loading of sludge onto trucks.

The same actions will be taken to reduce the risk of odour impacting the community as in the last shutdowns.

-

-

Temporary shielding will be put up around the sludge load out area to act as a wind break.

-

The sludge will be well wrapped to reduce the risk of any odour getting out.

-

The odour neutraliser will be used as needed.

-

Odour surveys will monitor odour.

-

Project Update - Dryer Replacement

The concept design of the new dryer facility is being comprehensively reviewed, and we are continuing to work through the requirements for resource consent applications. Huber have been selected as the supplier for the two new sludge dryers, and engineering design work is underway. We are working closely with Wellington Electricity on the design and construction of the new power supply. This keeps us on track with our delivery programme to have the new dryer available for use in December 2027.

UV Renewals Project starting soon

Later this month, we’re starting work to replace old UV (Ultra-Violet) disinfection equipment at the Seaview Wastewater Treatment Plant. This integrated UV disinfection system will improve treatment reliability and compliance and reduce the need for manual repairs and maintenance. It forms part of the plant’s wider renewal programme that is aimed at increasing its resilience and overall efficiency.

Crews have begun preparation work on site, and we’re expecting the new equipment to arrive from Canada in mid-December.

UV treatment will continue to operate, with temporary equipment in place while crews replace the old UV system. We don’t foresee any interruption to normal operation of the plant, or treatment of the wastewater and this work is not expected to generate any odour.

We expect this work to be completed in mid-2026.

Project Update - Odour Control

Stage 2 of the Odour Control Project is nearly complete. This stage involves physical upgrades to buildings and ducting systems to better capture and treat odorous air.

Key components include:

-

Installing a new air odour treatment unit for the milliscreen building,

-

Adding new ducting to capture air from the milliscreens,

-

Installing new milliscreen and biofilter fans to replace the existing fans, and

-

Repairing external ducting around the plant.

Upcoming works with an increased risk of odour

Most of this work is finished, but some final connections and installations have been delayed and are expected to be completed in December - as soon as the equipment arrives. A number of short shutdowns will be needed in November and December to safely install and test the new equipment. These will be as short as possible and scheduled to minimise disruption to the community.

Normal odour mitigations will be in place, with odour neutralisers used as required and odour scouting underway.

14th November

-

Installation of new isolation equipment upstream of the Biofilter Fans (there are two to install, one for each fan). This will allow each fan to be isolated from rest of the upstream odour system, reducing the risk of odour for future maintenance activities.

17th – 21th November

-

Installation of the second piece of new isolation equipment between the Biofilter Fan and the rest of the upstream odour system.

-

Replacement of a section of ducting on the Primary Sedimentation Tank’s odour extraction system. This work has a higher risk of odour than the other pieces of work. The final planning for this work is currently underway, and we will advise of any changes.

Late November – Mid December

Once the new isolation equipment is in place and the final connections for the new fans arrive, we will start installing the new fans. This work will require a few short periods (4-8 hours each) with an increased risk of odour, between late November and early December. Planning is underway, and we’ll confirm the details of this work closer to the time.

Abatement notice update

At the recent Community Liaison Meeting we talked about another component of the abatement notice, to install new odour treatment for the current dryer building. We undertook some additional work to make sure that installation of new odour treatment for the dryer building represented good value for money and would make a difference to offensive odour. We know that when the biological process at the plant is working well, any odour from the dryer is minimal, and smells similar to dog biscuits – very different to odour from other parts of the wastewater treatment process.

Through our investigation, we found:

-

Adding odour treatment on the current dryer building air will not noticeably reduce odour levels outside the plant boundary.

-

If completed, it would only be in place for a relatively short time, as the new dryer facility will be in a new building with its own dedicated odour treatment.

Because of this, Wellington Water recommended that the money (approximately $2m) is better spent elsewhere at the plant.

Together, Wellington Water, Hutt City Council and Upper Hutt City Council asked Greater Wellington to consider removing the requirement to upgrade the current dryer’s odour system from the abatement notice. This would avoid spending ratepayers' money on an upgrade that will not noticeably reduce odour levels outside the plant boundary and then won’t be needed once the new dryer is in place.

We are waiting for a formal decision regarding this request and will keep the community updated as it progresses.

Community Liaison Group Meeting

Slides and speaking notes

We have uploaded the slides and speaking notes from the Community Liaison Group to our website. If you have any questions or feedback, please don’t hesitate to email community@wellingtonwater.co.nz

Odour monitors

Due to some website issues, there has been a slight delay with the data from the odour monitors going live on our website. We expect this to be resolved in the next few weeks, and will advise you directly when they are up on the website. Check the slides from the Community Meeting for a sneak peek at the way this data will be displayed.

Thank you,

Blair Johnson

Head of Wastewater Contracts

Seaview Wastewater Treatment Plant Newsletter - October 2025

Kia ora koutou,

Welcome to the October Seaview Wastewater Treatment Plant Newsletter.

In this edition, you’ll find an update on:

-

general plant operations and maintenance,

-

dryer replacement and odour control projects,

-

upcoming extended dryer shutdowns, and

-

odour monitors.

Plant Operations and Maintenance: 1/9 - 30/9

Throughout September, Dissolved Oxygen and Mixed Liquor levels fluctuated slightly, largely due to the dryer maintenance. This was closely monitored to reduce the risk of any sustained issues. Dissolved Oxygen ended the month within target ranges, while Mixed Liquor ended the month slightly elevated.

Check out the graphs below for trends over time.

Following a number of high faecal coliform results, the plant went out of compliance from 17 September. This was related to the now-completed dryer maintenance works, and the performance of the aging UV system. The UV system renewal is expected to be completed in 2026. Our compliance is consistently monitored, and a summary of the full month’s compliance is published around the third week of the following month, here. [Seaview’s compliance is measured as a 90-day geometric mean and a 90-day 80th percentile. This means that in any 90-day period, not more than 18 days are permitted to be over specific set limits for things like suspended solids or faecal coliforms.]

Works for September included:

-

Urgent maintenance to the dryer, which required sludge loadouts and trucking between Friday 12th and Thursday 25th September,

-

Effluent pump maintenance,

-

A shutdown in the milliscreen room (part of the Odour Control project Stage 2).

Notifications were sent out for these, all of which held a low to moderate risk of increased odour. We received two odour complaints, and no assessments of objectionable and offensive odour.

Updated timeframe for extended Dryer Shutdown

Following the planned extended dryer shutdown in June this year, we informed the community that two further extended shutdowns were needed to complete important maintenance to the dryer. We can now advise that these will not occur until the first quarter of 2026 at the earliest. When we have a clearer picture of the timeframes, we will provide this information to the community.

Project Update - Dryer Replacement

The team is working on the concept design and procurement, with negotiations underway with preferred suppliers to continue our drive for efficiency and value for money. This project is a significant and complex piece of work, with long lead times for core pieces of equipment – including the dryers themselves.

The next major milestone is the concept design being completed, which is expected by the end of October. Downer (our design and build contractor) also expect to place the order for the two new sludge dryers around the same time. The new dryers will require new high voltage power supplies. This element of work is owned by Wellington Electricity, which is planning this in close co-ordination with our team.

With recent maintenance issues emphasising the need for a new dryer facility, delivering this project as quickly as possible remains a core focus for the team, and the wider organisation and councils.

Project Update - Odour Control

Progress is being made on Stage 2 of the Odour Control Project, with the Milliscreen ducting almost complete, and Air Treatment work on the Milliscreen Building well under way. Recently, we installed the air treatment ducting in the Milliscreen Hall, along with the external ducting and stack.

The Milliscreen building Air Treatment Unit is now in place and fans installed. Once up and running, this will improve safety for the treatment plant operators, and reduce the amount of untreated air released from the Milliscreen building.

New odour fans for the Milliscreen ducting and Biofilters arrived in late September. Their installation will require several odour system shutdowns, which may increase the risk of odour for short periods. We’re currently planning these shutdowns, and will share information as soon as possible.

As part of the wider Odour Control Project, work on the odour monitors is progressing well, with 4 of the 5 installed at the below locations:

The installed monitors will send live data to our website, which will be updated regularly to provide you with close-to real time information. We expect the website to be fully functional by the end of the month, and plan to provide a preview at the October 22nd meeting.

We are working through logistics for installation of the fifth monitor. We hope to have this installed soon.

Check out a photo of one of the installed monitors below.

Community Meeting

As a reminder, Wellington Water is hosting the annual Seaview Community Liaison Group meeting.

Time/date: 5:30pm, Wednesday October 22nd

Location: Pelorus Trust Sportshouse, 93 Hutt Part Rd, Moera, Lower Hutt

At the meeting, we will discuss the annual compliance report for Financial Year 2024/25, as well as providing an update on the Dryer Project, Odour Control Project, and odour monitors.

If you’re interested in attending, please RSVP via email to community@wellingtonwater.co.nz

Thank you,

Blair Johnson

Head of Wastewater Contracts

Seaview Wastewater Treatment Plant Newsletter - September 2025

Kia ora koutou,

Welcome to the September Seaview Wastewater Treatment Plant Newsletter.

A quick note on the change to our naming convention: Rather than referring to the newsletter by the month covered, we have shifted to the month that the newsletter is sent out in. So, while this newsletter covers August data, it is called the September newsletter.

In this edition, you’ll find an update on general plant operations and maintenance, the latest project updates, an update on the Dryer repairs, and information on the upcoming Community Liaison Group meeting on Seaview’s major projects and compliance.

Plant Operations and Maintenance: 1/8 - 31/8

Throughout August, Dissolved Oxygen levels remained steady within the target range. Mixed Liquor levels began the month just above the target range, dropped to within the target range and then rose slightly. While this is elevated, it is being closely managed and is not a risk to the biological process. Check out the graphs below for trends over time.

Project Update - Dryer Replacement

Now that Downer have been appointed as design and build contractor for the Dryer Replacement Project, the team are fully focused on completing the concept design and procurement of the main plant and equipment. This is a complex and detailed process, with significant investigation needed to make sure the new dryers are designed specifically for the community’s requirements. We anticipate that construction will have commenced by May next year.

For example, not all sludge is the same. The team had to test the specific sludge that moves through the Seaview Plant, to better understand its qualities. This information is vital to make sure that the dryer is designed in the right way, so it can dry the sludge efficiently. This involved sending a sample of the sludge all the way to Germany for testing by an equipment supplier.

We’ll share more information on the road ahead as we work towards making the new dryer facility available for use in December 2027.

Project Update - Odour Control

Stage 2 of the Odour Control Project has gotten off to a strong start, with a series of brief shutdowns to the Milliscreen room in August and early September now completed. This was part of our work to replace the existing ducting and fans, to reduce odour escaping from the equipment into the building and then to outside.

Construction continues onsite with the completion of the Milliscreen ducting due early September. Construction has also started for the Milliscreen Building Air Treatment Unit with the slab being poured this week. In the following month ducting for this system will be installed to take air from the Milliscreen building to the new air odour treatment unit. Once commissioned this will make the working environment for the treatment plant operators safer and reduce the amount of untreated air from the Milliscreen building being released.

New odour fans for the Milliscreen ducting and Biofilters are due to arrive on site in late September. The installation of these will require several odour system shutdowns which may increase the risk of odour for short periods. We’ll share information about these shutdowns closer to the time.

This project is focused on improving the way that we capture and treat odourous air at the plant, to reduce the risk of odour impacting the community.

Dryer repair update

Thank you again to the community for your patience and understanding as we have worked to complete this repair.

The majority of the work has been completed, which has allowed us to bring the dryer back online. However, to address the remaining backlog of wet sludge that built up while the dryer was offline, we will continue to load out and truck sludge to the Silverstream Landfill until approximately the end of this week. This will protect the biological process and help make sure the plant remains healthy and balanced.

Site surveys and community odour scouting continue to indicate that any odour (over and above the odour from the plant itself, and everyday operational maintenance) is directly related to the wet sludge being unloaded. We expect that this will disperse once the remaining wet sludge has been removed.

Community Meeting

Wellington Water would like to invite you to the annual Seaview Community Liaison Group meeting, on Wednesday October 22nd at Pelorus Trust House.

At the meeting, we will discuss the annual compliance report for Financial Year 2024/25, as well as providing an update on the Dryer Project and Odour Control Project.

If you’re interested in attending, please RSVP via email to community@wellingtonwater.co.nz

Seaview Wastewater Treatment Plant Newsletter - August 2025

|

|

|

|

|

|

|

|

|

|

|

|

|

Seaview Wastewater Treatment Plant Newsletter - June 2025

|

Kia ora koutou, Welcome to the June update of the Seaview Wastewater Treatment Plant Newsletter. In this edition, you’ll find the close-out of the Dryer Shutdown works, an update on general plant operations and maintenance, improvements to how we communicate odour risk, an update on the Dryer Replacement and Odour Control Projects, and a Q&A with one of our Odour Scouters. |

|

Dryer Shutdown It was great to see the Seaview dryer shutdown and maintenance works completed ahead of schedule. Works were conservatively scheduled to take place between June 3rd and 17th, and we were able to confirm that the works had been completed and the dryer brought back into service by Friday 13th. The plant’s biological process was well managed, and remained healthy and balanced throughout the works. This helped manage the risk of odour, alongside the practical mitigations on site and the weather conditions. As previously advised, planning for the next extended shutdown is already underway. We’ll keep you posted as planning progresses. |

|

Plant Operations and Maintenance Throughout June, Dissolved Oxygen levels remained steady within the target range. Mixed Liquor levels began the month within the target range, and ended just above – this was due to the dryer shutdown works. The effluent quality and sludge settleability has improved. As you can see in the graphs below, both metrics have remained steady and close to the target range.

The plant was in compliance with the resource consent for treated wastewater, except for faecal coliform limits on the 1st June only. This is based on results for Biochemical Oxygen Demand (BOD), total suspended solids and faecal coliforms. The faecal coliform limits were impacted by heavy rain in late May. Outside of the dryer shutdown and general maintenance, some work on the milliscreens was notified to the community due to odour risk. We received 0 odour complaints and 0 assessments of objectionable and offensive odour. |

|

Improvements to how we communicate the Plant’s odour risk Since last December, the overall biological process of the plant has remained healthy and balanced. This biological process is managed by a system of controls, two of which (Mixed Liquor and Dissolved Oxygen) have been reported on regularly, as they were particularly relevant following the issues late last year. However, they are a small snapshot of a much bigger picture, and focussing on these metrics alone may be misleading. Following feedback, we have identified that we can provide more relevant and helpful information to the community by instead sending out regular updates on how the wider biological process and whole system is operating. What does this mean for our weekly communications? We will continue to provide weekly updates to advise of any planned works for the week ahead which have an increased risk of odour, over and above the odour from the plant itself and everyday operational maintenance. We will also provide direct notifications if any urgent works are needed that have an increased risk of odour. If the health and balance of the plant is compromised and there is a risk of increased odour, we will notify you as and when needed. However, we will cease providing weekly updates on Mixed Liquor and Dissolved Oxygen, and will shift to regularly reporting on the wider biological process and operational activity at the plant on a monthly basis. We hope that this will help you better understand how the plant manages the risk of odour, and get the relevant, useful information you need. |

|

Project Update - Dryer Replacement The project is entering the final phases of the tender process, and we expect to be able to announce a contractor at the end of July. |

|

Project Update - Odour Control HEB Construction has been engaged for Stage 2 works, which include improvements to the milliscreen room and the building which houses the dryer. Physical works are due to begin soon, beginning with the repair of external ducting. This work does not increase the risk of odour. As the team build out their work plan, we have been notified that some components of work may carry a brief increased risk of odour. This risk is contained to between a few hours and a day for each piece of work, and will be staggered throughout late July to October. We expect to have specific dates in the coming weeks, and will notify the community ahead of time through the interested parties list. If you aren’t signed up and would like to receive these notifications, please email customer.notifications@wellingtonwater.co.nz Work is going well on the odour monitors, and we are making headway on the web interface which will make the information publicly available. As a reminder, the indicative locations are marked on the map below.

|

|

Q&A with an Odour Scouter As you may know, odour scouters are often deployed during major projects like the odour control project to scout around the community to help identify and understand odour. We sat down with one of the odour scouters to ‘lift the lid’ on how they do this helpful mahi. Check out our Q&A with Dom below! Q: What does an odour scouter do? A: Odour scouters help keep a finger on the pulse of how the spread and intensity of odour throughout the community changes over time, and identify significant odour sources at places like wastewater treatment plants. At Seaview, the results from odour scouting help inform the team working on the plant of any issues which need to be addressed to limit the spread of odour beyond the plant boundary. Our main job as odour scouts is to travel to different spots in the community around Seaview Wastewater Treatment Plant, and check for any unpleasant or abnormal smells which could be coming from the plant. We then head back to the plant to trace back what part of the treatment process the unpleasant odours may be coming from. Q: Why did you become an odour scouter? A: When the opportunity to become an odour scout for Seaview came up, I was very keen to take it on. I know that the odour problem has been really hard on the community and that the situation at the treatment plant is also pretty challenging. I thought I could help out by mapping out the spread of odour throughout the community and tracing any unpleasant odours from the plant back to the source. Q: What does a typical odour scouting session look like? A: First, we check which way the wind is blowing - usually it blows from the north or the south. This determines which direction it blows odour from the plant. For example, if the wind is blowing from the south, we'll visit community locations which are north of the treatment plant to monitor the odour there. When we’re odour scouting, we’re literally following our noses! To this day, the human nose remains the most accurate measure of odour. To become an odour scouter, I had to go through training. This included having our noses trained to recognise different types of odour, like earthy, foul or rotten, and eggy. We’re also trained to observe and measure the levels of odour in a consistent way. The type of smell can tell us if there’s an issue, and where it’s coming from. For example, the dried solids from the dryer building can smell like dog biscuits! After assessing odour in the community, we go straight to the usual odour sources at the treatment plant and also take measurements there, so we can identify which ones are being problematic and why. At the end of the session, we report the results back to the team for them to analyse. |

|

Thank you, Blair Johnson |

|

Keep in touch! You are receiving this email because you have expressed an interest in the plant. Please feel free to share this with others who may be interested. Join the mailing list for plant notifications and this monthly update, at customer.notifications@wellingtonwater.co.nz. If you have any questions relating to this newsletter email community@wellingtonwater.co.nz. For complaints relating to specific incidents or properties go to customer@wellingtonwater.co.nz. |

Seaview Wastewater Treatment Plant Newsletter - May 2025

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Seaview Wastewater Treatment Plant Newsletter - April 2025

|

Kia ora koutou,

Welcome to the April edition of the Seaview Wastewater Treatment Plant Newsletter. In this edition, you’ll find the latest information on plant operations and maintenance, upcoming works at the plant, an update on the Odour Control project, and a future community meeting on the Odour Treatment and Dryer Projects. |

|

|

|

Plant performance and operations Throughout April, the health and balance of the plant remained largely steady, with a slight uptick in Mixed Liquor and Dissolved Oxygen levels towards the end of the month. We end the month with Dissolved Oxygen within the target range, and the team continue working to bring to bring Mixed Liquor back into range. This can take time as we are working to balance a complex biological process.

We delved a little deeper into how this work is done in the March newsletter, which you can read here. We’ll continue to keep you up to date with our efforts via the regular weekly update. |

|

|

|

It is heartening to look back at these measurements and see the averages hold steady since the height of the odour issue in last October. You can see a high-level summary in the graphs below, with the target range indicated in light green. |

|

|

|

|

|

The plant has remained in compliance of the resource consent for treated wastewater. This is based on results for Biochemical Oxygen Demand (BOD), total suspended solids and faecal coliforms. While levels for all three parameters have been back within the target range for daily compliance since mid-December, we have been in full compliance since 1 March. This lag is due to the relevant measurement being based on a 90-day statistic.

Both regular maintenance and reactive maintenance works occurred across the month, including the repair and refurbishment of milliscreens, refurbishment checks to the main effluent pumps, and essential maintenance of the seed silos which is ongoing. All of these works were communicated to the interested parties list.

Across April, we received 0 odour complaints and 0 assessments of objectionable and offensive odour. |

|

|

|

Seaview Community Meeting We will be holding a community meeting to provide an update on the Odour Control Project, the Dryer Replacement Project, and the upcoming Dryer Shutdown. Representatives from Wellington Water and Hutt City Council will be present, along with the project teams ready to answer your questions. The meeting details are below: Venue: Pelorus Trust Sports House (93 Hutt Park Rd, Moera, Lower Hutt) Time: 5:30pm - 6:30pm Date: Wednesday 28th May Please RSVP to community@wellingtonwater.co.nz to give us an indication of numbers. |

|

|

|

Project Update - Odour Control

Following a robust tender process, we’re able to announce that HEB Construction Limited have been engaged to deliver the Stage 2 works for this project. Significant planning will take place over the next few months, alongside the procurement of the required parts. The new odour control units are scheduled for installation in September. The programme is tight, but we remain on track to complete the Stage 2 work by December 1st this year.

The Project team will be at the upcoming community meeting to share more information and answer your questions about this work. |

|

|

|

Dryer Maintenance and Shutdown

As was advised in last week’s update, we are currently planning an extended shutdown of the Dryer to complete critical maintenance.

The Seaview Dryer is essentially coming to the end of its design life, and requires constant maintenance to give it the best chance of functioning reliably until a new dryer is fully commissioned.

We can now confirm that in order to renew multiple components, the current dryer will be taken offline between Tuesday 3rd June and Tuesday 17th June. Doing this work all at once aims to minimise disruption to the plant’s operations and increase efficiencies. This work includes: |

|

|

|

Thank you, Linda Fairbrother Blair Johnson |

Seaview Wastewater Treatment Plant Newsletter - March 2025

Seaview WWTP Newsletter

March 2025

In this month’s Seaview Newsletter, you’ll find information on:

-

Plant performance and operations

-

Actions from the Community Meeting

-

Project updates

-

How we monitor and control Mixed Liquor and Dissolved Oxygen Levels

Plant performance and operations

Throughout March, the health and balance of the plant has remained stable. Further detail on these parameters is at the end of this newsletter.

The resource consent for treated wastewater is based on results for Biochemical Oxygen Demand (BOD), total suspended solids and faecal coliform. Levels for all three parameters have been back within the target range for compliance since mid-December, and has been in full compliance since 1 March. The lag in achieving full compliance is due to the relevant measurement being based on a 90-day statistic.

Following the completion of the refurbishment works on Primary Sedimentation Tank (PST) #2, all four PST’s are in full operation. No other works with an increased risk of odour have been carried out this month. One final PST requires refurbishment, and this is being planned for the coming months.

We received 15 odour complaints in March, with two assessments of offensive and objectionable odour arising from these complaints. In February, we received 7 odour complaints.

Actions from the Community Meeting

Odour Monitoring

We are in the final phases of putting together the plan for odour monitors around the Seaview area.

The odour monitors selected pick up on Hydrogen Sulphide, or H2S, in the air. H2S has a distinctive ‘rotten egg’ smell. It’s one of the most common odours experienced from wastewater treatment plants and is monitored around the Christchurch wastewater treatment plant at Bromley.

The below criteria have helped us identify five locations for the monitors to be installed.

Core criteria

-

available space and resources on site to host the sensors,

-

ease of access, and

-

low risk of vandalism

Inside Seaview Wastewater Treatment Plant

-

near potential odour sources, such as treatment aeration basins, sludge processing units, and discharge points

Community Locations

-

predominant wind directions – up and downwind of the Seaview WWTP

-

near known complaint hotspots

Using these criteria, we’ve identified five key locations. Read the below, and let us know at community@wellingtonwater.co.nz if you have any feedback. We know it’s important we get these monitors placed as soon as possible, so we’d appreciate your feedback being sent through by Tuesday 15th April.

Proposed locations

Inside the Plant

Seaview Plant Entrance (Northern): This site is located at the northern tip of the plant. It is positioned to capture odour levels as they leave the plant and spread out in the northeast direction.

Return Activated Sludge (RAS) Pump Area: This is at the southern end of the site, it is positioned to capture odour levels as they leave the plant and spread out in the southern direction.

In the community:

Meachen Street, south of the plant: This commercial/industrial area positioned south of the plant is expected to provide useful data. This area is known to be affected by odour.

Pelorus Trust Sports House: This site is immediately north-east of the plant, in an area with high recreational use. It will help us monitor the odour impact on nearby residential areas and community facilities.

Gracefield School: Located further north-east of the plant, it is an important location for monitoring odour levels. It also provides a broader understanding of odour dispersion patterns.

Communications

We continue to provide updates as needed, plus regular weekly and monthly communications. We have updated our website with key metrics to help the community understand the short-term risk of odour. Work continues on a Seaview plant odour ‘heat map’, and we’ll update you further when we have preliminary designs in the coming weeks.

Project Update - Odour

Stage 2 – Dryer building, Milliscreening building and ducting

We’re working through the tenders received for Stage 2 works, and are on track to have a contractor engaged by the end of April with construction to follow.

Stage 2 includes:

-

-

Installation of new odour treatment in the dryer building,

-

Installation of new odour treatment in the milliscreening building, and

-

Replacement of the ducting and fans for odour extraction from the milliscreens.

-

Project Update - Dryer Replacement

We have completed the evaluation of expressions of interest from potential contractors, and expect to release the Request for Tender in mid to late April. At this stage, we expect to have a contractor in place for Stage 1 works by the end of July.

Monitoring and control of Mixed Liquor and Dissolved Oxygen Levels

For the past few months we have been providing weekly measurements of the Mixed Liquor and Dissolved Oxygen levels at the plant. As you know, these are key to helping us understand the health and balance of the plant, which in turn can help us understand the level of odour to expect.

These are both monitored regularly, so if there are any significant changes outside of the target range, we can quickly take action. Readings for the past two months are below. This March came to a close with Mixed Liquor slightly above the target range and Dissolved Oxygen comfortably within target.

Mixed Liquor Suspended Solids (MLSS) is sampled daily, and largely depends on the amount of sludge that is removed from the plant. It is a measure of the amount of microorganisms in the treatment plant. When it’s around the right level, it helps us treat wastewater by efficiently and effectively breaking down pollutants.

When it’s moving away from the target range, we have a few levers to pull to get it back inline. These work gradually, and include increasing sludge removal from the plant and adjusting the aeration, which brings us to:

Dissolved Oxygen. Providing the right range of Dissolved Oxygen gives the bacteria and other microorganisms the best conditions to grow. This helps the plant’s biological process work as it should. Dissolved Oxygen levels are monitored every 5 minutes, around the clock. When levels are too low or too high, we adjust the aeration to try to gradually bring it back into the target range.

Thank you,

Linda Fairbrother

Project Lead, Major Projects

Blair Johnson

Head of Wastewater Contracts

Seaview Wastewater Treatment Plant Newsletter - February 2025

Seaview WWTP Newsletter

February 2025

Kia ora koutou,

In this month’s Seaview Newsletter, you’ll find information on upcoming works, plant performance and operations, odour scouting, an update to our website to help you plan for potential odour, and detecting petrochemicals in the wastewater network.

Plant performance and operations

Throughout February, we’ve continued to keep a close eye on the Mixed Liquor Suspended Solids and Dissolved Oxygen levels, which are key indicators for the health and balance of the plant. When they are within target range, we can expect odour to be at a minimum, unless there is an operational issue at the plant.

Over the past 4 weeks, Mixed Liquor has remained steady slightly above the target range, and Dissolved Oxygen levels are within the target range.

Routine maintenance occurs every day at the plant, but we have had four instances of reactive maintenance which have held the risk of an increased level of odour. We have continued to communicate these through our Interested Parties list, and on social media as needed. If you or anyone you know would like to sign up to this list, please email Customer.Notifications@wellingtonwater.co.nz

Daily treated wastewater quality results such as Biochemical Oxygen Demand (BOD), total suspended solids and faecal coliform levels have been within the target range for compliance since mid-December.

Between 1 and 28 February, we received 6 odour complaints. This is steady with recent months.

Upcoming work

As you may remember, while refurbishment of Primary Sedimentation Tanks (PST) #3 and #4 was completed last year, PST #1 and PST #2 are both due for refurbishment. This refurbishment will help reduce the risk of issues moving forward, and bring PST #2 back into full operation.

Refurbishment on PST #2 began on the 27th of February and is going well. It will take around 2 weeks to complete. First, PST #2 will be isolated and drained down. Then, it will be cleaned. This stage of work is the most likely to cause increased levels of odour, so it will be completed at night. Once the cleaning is complete, the team will complete the refurbishment.

Throughout these works, we will be using the odour neutralisers as needed. We will also continue undertaking odour surveys onsite to monitor odour, and will advise of any changes or issues directly.

Planning for the refurbishment of PST #1 will be undertaken as soon as we complete the works on PST #2. We are still on track to complete the works by the end of June.

Project Update - Odour

Stage 2 – Dryer building, Milliscreening building and ducting

Work continues on the tender process. We are on track to have a contractor engaged by the end of April with construction to follow.

As a reminder, Stage 2 includes:

-

Installation of new odour treatment in the dryer building,

-

Installation of new odour treatment in the milliscreening building, and

-

Replacement of the ducting and fans for odour extraction from the milliscreens.

Project Update - Dryer Replacement

The project to replace the sludge dryer is well underway, and we continue to explore ways to speed up delivery. We are continuing the procurement process, and the team has begun evaluating expressions of interest from contractors.

Website update – helping the community predict odour levels

The level of odour experienced by the community is influenced by many variables, including internal factors like the health and balance of the plant and plant maintenance and operations, and external factors like the wind, weather, and location.

Due to this, it can't be forecast with a high level of confidence. What we can do is monitor the internal factors at the plant which can give an indication of possible odour, and communicate these clearly with residents.

In order to do this, we have updated the Seaview Wastewater Treatment Plant webpage with a section that shows these key factors at a glance, and gives you an indication of the level of odour you can expect in the week ahead.

These factors are the health and balance of the plant, and plant activity.

We monitor the health and balance of the plant through the levels of Mixed Liquor Suspended Solids and Dissolved Oxygen. Mixed Liquor Suspended Solids measures the volume of solids in the aeration tanks where bacteria feed on organic material in the wastewater. Providing the right range of Dissolved Oxygen gives the bacteria the best conditions to grow. When they are within target range, it means that the biological processes at the plant are generally healthy and well-balanced, which gives an indication of the level of odour we can expect.

Plant activity consists of general day-to-day operations, planned maintenance and urgent, reactive maintenance. Each piece of work is assessed for the risk of increased odour, and we work to give you this information with as much notice as possible.

Odour scouting

Previously, odour scouting has been undertaken around the community during live project works and when significant maintenance is being completed that has a high risk of increased odour.

With the next stage of the odour project moving through the tender process, and no maintenance with a high risk of increased odour planned, odour scouting around the community has been placed on hold.

Odour surveys at the Seaview Plant will continue, and we will continue to monitor the situation. If anything changes, we can quickly stand up the odour scouting team again.

Detecting petrochemicals to protect the plant

When dumped in the wastewater network, rather than properly disposed of, petrochemicals can have a significant impact on the biological processes at the plant. This can then cause increased odour, and be costly to clean up – in the ballpark of $50,000 each time!

As with most things, the best cure is prevention, but it’s important we also take steps to reduce the impact of petrochemicals on the plant if they do make their way into the system. To do this, we’re currently trialing a sensor that can detect hydrocarbons (commonly found in petrochemicals) in the incoming wastewater.

The end goal of the trial is to see if we can roll this technology out across the wastewater network – watch this space!

Thank you,

Linda Fairbrother

Project Lead, Major Projects

Blair Johnson

Head of Wastewater Contracts

Seaview Wastewater Treatment Plant Newsletter - January 2025

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Seaview Wastewater Treatment Plant Newsletter - December 2024

Seaview Wastewater Treatment Plant Newsletter - December, 2024

Your latest news on what's happening at the Seaview Wastewater Treatment Plant

Kia ora koutou

This special edition of the newsletter provides a summary of the findings from Part 1 of the odour neutraliser shutdown trial which finished on 18 December. We also provide an update on the actions arising from the community meeting held on 25 November, together with details of the current status of the plant and operations over the Christmas/New Year holiday period.

Odour neutraliser shutdown trial

Thanks to everybody who’s completed the survey so far. Part 1 of the trial to shut down the odour neutraliser finished on 18 December and the odour neutraliser was turned back on at 8am Thursday 19 December. Part 2 of the trial is to leave the odour neutraliser running for another two weeks until 2January 2025.

Please continue to complete the survey until 2 January 2025. This will help us establish a ‘baseline’ from which we can assess the trial to help us understand whether the smell is better, worse or the same as it has been before the shutdown. We acknowledge the plant has not been in a normal operating state and will take that into account.

The odour survey is simple and very quick to complete. We appreciate your help with this.

We will continue to keep you updated on the progress throughout this next stage of the trial period via our interested parties’ email and our Facebook page - https://www.facebook.com/wellingtonwater.

Following the completion of the trial, we will undertake a process of review and assessment of the results. We will keep you informed as we work our way through this in the New Year. Feedback from the community will help Wellington Water and Hutt City Council determine our next steps.

A summary of the discussions at the meeting and issues raised, presentations from speakers alongside a Q&A document will be made available on our website over the next week. We will send out a link to this once it has been published.

Summary of responses so far from the trial

We received 241 responses to the survey over the period of Part 1 of the trial. Responses to the survey have been relatively low but we did receive a significant number of responses (119) on 6 December.

Odour levels during Part 1of the trial period confirm that odour remains an issue at the plant. The results show varying levels of impact based on location and weather conditions.

|

Rate the smell between 1 and 5 |

How does the smell compare to previous months |

||||||||||||

|

|

|

Of responses rating the odour at 4 or 5, how did the odour compare to previous months |

||||||

|

Odour levels were most frequently and strongly smelt at Seaview and Waiwhetu.

|

Seaview |

Waiwhetu |

|

83 respondents 56 rated odour at 4 or 5 |

60 respondents 28 rated odour at 4 or 5 |

During the trial, odour scouting was also undertaken daily. The findings of the odour scouts align with improvements in plant health and feedback received from the community. The winds were predominantly northerly meaning more odour was observed south of the plant than north. Odour levels were strongest in locations closest to the plant and in areas at the plant where work was being undertaken. Scouting is planned to continue 1-2 days per week in the New Year.

During the period of the trial, work has continued to bring the plant back to optimal operational performance and reduce the risk of increased odour levels over the holiday period. We appreciate this makes it challenging to make an accurate assessment of the effectiveness of the odour neutralisers. This means the results of the survey and odour monitoring need to be considered in the context of work at the plant that may lead to increased odour levels (e.g. transporting dewatered sludge to landfill) and other changes to processes at the plant to increase solids processing (e.g. Dissolved Air Flotation optimisation trial). Further details about this work and the current status of the plant are provided further in this newsletter.

A summary of the responses received from Part 1 of the trial (4-18 December) is available on our website – see https://www.wellingtonwater.co.nz/assets/The-Network/Wastewater/Wastewater-Treatment-Plants/Seaview/Odour-neutraliser-trial-survey-results_Part-1_website.pdf

Plant performance and operations

Current status of the plant

We have made good progress in the past month and the plant is now close to normal operations. Our recent monitoring has indicated that with the reduction in sludge levels at the plant, odour levels have also generally reduced.

Two key indicators of the health and balance of the biological process at the plant are levels of Mixed Liquor Suspended Solids (MLSS) and Dissolved Oxygen (DO). MLSS measure the volume of solids in the aeration tanks where bacteria feed on organic material in the wastewater. Providing the right range of Dissolved Oxygen (target range 1 to 3), gives the bacteria the best conditions to grow.

Below is a summary of how these indicators have been tracking since the outages with the dryer in September and October.

|

|

Mixed Liquor Suspended Solids (MLSS) |

Dissolved oxygen (DO) |

|

9 October |

5,760 |

0.69 |

|

23 October |

5,070 |

0.67 |

|

5 November |

5,230 |

0.83 |

|

19 November |

4,800 |

0.67 |

|

4 December |

4,350 |

0.69 |

|

18 December |

2,560 |

2.11 |

While there is still some work to do to return the plant to the level that it was operating at before the incidents with the dryer, we are pleased to see a marked improvement in both indicators.

Operations over the holiday period

Preliminary cleaning of Primary Sedimentation Tank #2 has been completed in advance of repairs to be undertaken after parts arrive in mid-January. Work on the repair to Blower #2 has also been completed.

To keep the plant stable and minimise odour, we will be limiting planned maintenance and pausing non-critical work at the plant over the holiday period. The trucking of dewatered sludge to landfill will also stop from end of day Friday 20 December.

Routine operation of the plant and dryer will continue. Veolia, our plant operators will be monitoring key process points of the plant during the holiday period. Work has been undertaken to build resilience to plant operations, with resources on call and escalation processes in place to respond to any incidents that may arise.

The weekly updates on odour levels and plant operations recently provided will stop over the holiday period. We will follow our usual procedures for notification to the community of any unplanned outages, maintenance or operational incidents at the plant.

Actions from the community meeting

A summary of the notes from the community meeting held on 25 November, as well as a copy of the presentation on plant operations has been published on our website – Seaview Wastewater Treatment Plant Community Meeting Notes, Actions, and Presentation Slides.

Increased odour monitoring

We are continuing to investigate the right type of monitors that we could use to increase our monitoring of odour from the plant. We have met with the team at Christchurch City Council about the monitors that they have used. Our engineering team are completing their initial evaluation, and we will provide a further update in the New Year.

Updates on potential for high odour levels

We have continued to provide weekly communications to the community about operations at the plant that could impact on odour levels via our interested parties email list and posted updates on our website and Facebook page.

We are committed to making this information as accessible and transparent as possible so are looking at other formats to present these updates and to increase visibility on our website. We acknowledge that wind direction impacts odour levels and will explore how we can provide this as an added layer of information on our website.

We will keep you updated on progress with this work which requires further investigation and changes to our website.

Keep in touch

You are receiving this email because you have expressed an interest in the plant. Please feel free to share this with others who may be interested.

-

Join the mailing list for plant notifications and this monthly update at customer.notifications@wellingtonwater.co.nz.

-

If you have any questions relating to this newsletter email community@wellingtonwater.co.nz.

-

For complaints relating to specific incidents or properties go to customer@wellingtonwater.co.nz.

Thank you!

Blair Johnson

Head of Wastewater Contracts

Seaview Wastewater Treatment Plant Upgrades - November 2024

Seaview Wastewater Treatment Plant Newsletter - November/December, 2024

Your latest news on what's happening at the Seaview Wastewater Treatment Plant

Kia ora koutou,

Welcome to the regular update about the operation of the Seaview Wastewater Treatment Plant and the programme of upgrade work. This is the last newsletter for 2024 but email updates will continue, and you can find the latest information on the website.

In this issue

-

Community meeting update

-

Next steps

-

Update on work at plant

-

Wastewater Treatment Plants Treatment Services contract review

-

Plant performance update

-

Keep in touch

Community meeting update

Thank you to those who attended the community liaison meeting on Monday 25 November.

We know it has been an extremely stressful time for the community. We appreciated the opportunity to have a face-to-face conversation to discuss recent issues that have resulted in increased odour from the plant.

The Mayor of Lower Hutt, Wellington Water Chief Executive and staff, and senior management from plant operators, Veolia, spoke at the meeting. Chief Executive, Hutt City Council Jo Miller was also in attendance. They all reiterated that the Seaview Wastewater Treatment Plant is a top priority and that the level of odour is completely unacceptable. However, all speakers also emphasised that there is no quick fix or silver bullet to reducing the odour from the plant. It is likely there will be intermittent occurrences of increased odour at the plant for a while as we work to replace and upgrade aging equipment at the plant.

Community members spoke about the emotional toll of the stench and the ongoing impact on their wellbeing, their businesses, and their house prices.

All speakers acknowledged the huge impact on the community. Mayor Campbell Barry said what the council can do is give people confidence that everything possible is being done to fix the problem.

Wellington Water's CE Pat Dougherty assured the community that Wellington Water and Veolia would be doing all they could to minimise odour over the holiday period. This included avoiding any maintenance or upgrades that might cause odour levels to increase.

We were especially grateful that the meeting was conducted respectfully, with a safe space for all speakers to talk freely and share information without interruption. We appreciate all the questions and comments from the community which have given us some things to take away and review.

In response to the concerns raised by the community at the meeting, we are working on three key actions/next steps:

-

Turning off the odour neutralisers to see if this reduces the impact on the community, without increasing odour effects.

-

Increase monitoring of odour from the plant.

-

Providing the community with more timely and frequent information about the likelihood of high odour levels from the plant so people can plan.

A summary of the discussions at the meeting and issues raised, presentations from speakers alongside a Q&A document will be made available on our website over the next week. We will send out a link to this once it has been published.

|

Next steps

To help us to assess the impact and effectiveness of the trial, we are asking the community to fill in a quick online odour survey daily to let us know of your experience of odour levels. You can fill in this survey up to three times a day – morning, noon, and evening or whenever you notice a smell.

If there is significant negative impact experienced by the community during the trial, it will be shut down earlier than planned. We will be monitoring feedback, odour scouting results and complaints very closely throughout the trial.

Increased odour monitoring

We need to consider the types of monitoring that will be fit-for-purpose for our environment, and this may take us a bit of time. We are working on this, and we have our engineering team exploring options.

Once we have further information and options to do this, we will seek community feedback and input.

More timely and frequent updates on potential for high odour levels

As this requires further investigation and changes to our website, this is not something we can do immediately. We will keep you updated on progress via email.

|

||||

|

Update on work at the plant

The recent sludge dryer outages caused a backlog of sludge in the system, throwing the biological waste treatment process out of balance. This contributed to the odour, as did the need to truck sludge that had not been dried to the landfill.

The dryer is now back online, and we are making progress with clearing the backlog. However, we will need to keep intermittently trucking some sludge to the landfill to help clear the backlog as quickly as possible. This is scheduled to resume on Tuesday, 3 December. We have erected scaffolding and cover in the area where sludge is being loaded to reduce the odour when this process is being undertaken.

Improvements in the biological process have been noted and we are doing all we can to get the process back into balance with the plant operating at design levels as soon as possible.

The reports on the fire and mechanical failure will be made available on our website when completed.

|

||||

|

Wastewater Treatment Plants Services contract review A review of the Wastewater Treatment Plants Services contract was recently completed. You can read the full report on the review which has been published on our website.

Plant operators Veolia are reorganising their operations at Seaview and other plants they operate under contract to Wellington Water.

Following the review Veolia have engaged a global taskforce to enhance access to international expertise, invested in further staff training, updated their communication structures to meet the needs of stakeholders and regulatory compliance, and ensured clear organisational focus on critical areas including preventative maintenance.

Go to our website to read the full report of the review - https://www.wellingtonwater.co.nz/assets/Reports-and-Publications/RWWTP-Review-Cover-note-and-report-..pdf

Plant performance update

The dashboard also confirms that the plant remained non-compliant for faecal coliforms because the treated effluent has exceeded the set limit for bacteria on more days than permitted over a 90-day period. The level of risk to public health is low because this is treated wastewater which is pumped into the sea near Pencarrow Head/Te Raeakiaki, where it is quickly diluted.

The Annual Resource Consents and Compliance reports for the Seaview Wastewater Treatment Plant have also been published on our website.

The performance dashboard for October and Annual Resource Consents and Compliance report can be viewed on our website – go to

Keep in touch You are receiving this email because you have expressed an interest in the plant. Please feel free to share this with others who may be interested.

community@wellingtonwater.co.nz.

Thank you for taking the time to read this information. Be assured we are doing all we can to avoid offensive odours from the plant over the summer.

We wish you all the best for the holiday season.

|

Seaview Wastewater Treatment Plant Newsletter - October 2024

Seaview Wastewater Treatment Plant Newsletter -November 1, 2024

Your latest news on what's happening at the Seaview Wastewater Treatment Plant

|

|||||

|

|||||

|

|||||

|

|||||

|

|||||

|

|||||

|

|||||

|

|||||

|

|||||

|

|||||

|

|||||

|

Seaview Wastewater Treatment Plant update - September 2024

Seaview Wastewater Treatment Plant Newsletter -October 3, 2024

Your latest news on what's happening at the Seaview Wastewater Treatment Plant

Kia ora koutou

Welcome to the monthly update about Wellington Water’s operation of the Seaview Wastewater Treatment Plant and the programme of upgrade work.

You’re receiving this email because you expressed an interest in the plant. Please feel free to share this with others who may be interested.

You can join the mailing list by emailing customer.notifications@wellingtonwater.co.nz.

In this issue:

-

Community message

-

Sludge dryer back in service

-

Biofilter air distribution system renewal

-

Odour Treatment Renewal Project

-

Ultraviolet disinfection upgrade

-

Primary sedimentation tank mechanical renewal (second tank)

-