Wastewater treatment process

All treatment plants are slightly different, but the process is generally similar,

Entering the treatment plant

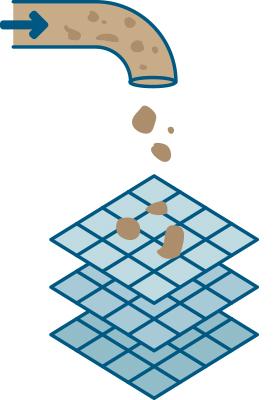

As wastewater enters a treatment plant it is passed through milliscreens. These are made of fine mesh (about two millimetre wide openings) and act as a sieve to stop any large solids in the wastewater getting through, such as wet-wipes, sanitary products, shampoo bottles, toys, plastic bags, etc. Everything that doesn’t make it through the screens is collected, pressed to squeeze out the excess water, and then transported to a landfill. The liquid that does make it through the milliscreens then flows through a pipeline into an aeration basin.

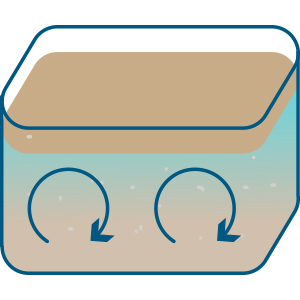

Aeration basins have air blown in to feed the bacteria and keep everything mixed. The aeration process allows environmentally friendly bacteria to feed on the nutrients in the wastewater sludge, such as fats, sugar, and ammonia from body waste. Aeration can take several hours, during which clusters of bacteria form as they break the waste down. *Some of our larger treatment plants also have settling tanks between the milliscreens and aeration basins. These use gravity to remove large particles.

In the clarifier the clusters of bacteria are separated from the liquid. This is because the clusters of bacteria are heavier and sink to the bottom of the clarifier as “sludge”. The clarifier also has a sloping floor, which assists with gravity separating the solid particles. The liquid flows over the outside walls of the clarifier, separating it from the solids, so it can then be treated.

From the clarifier, most of the settled ‘sludge’ is pumped back to the aeration tank. This is because the aeration tank needs a certain bacteria population to maintain the aeration process. The exact amount is calculated and adjusted every day.

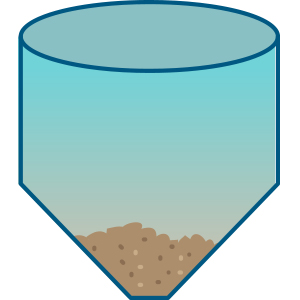

Separation of solids from liquids - de-watered sludge

The solid sludge that does not go back to the aeration tank is pumped to a thickener or directly to centrifuges.

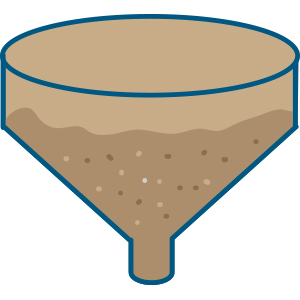

The sludge is then pumped to a centrifuge where it’s mixed with polyelectrolyte - a substance that helps bind the solids and separate the water. The centrifuge acts like a spin dryer, as it spins the contents at a high speed causing the solids to stick to the outside of the ‘bowl’ and any leftover liquid to the centre. This liquid is sent back to the aeration basin, whilst the de-watered sludge drops into large containers and is removed for disposal at landfills or further treatment.

We are currently investigating other ways to dispose of/ find better uses for the solids separated at wastewater treatment plants. One way we are looking at is thermal drying to produce a product that is safe to use as a fertiliser.

Separation of solids from liquids - treated water

There are a number of treatment options for the liquid in order to remove the remaining bacteria and viruses down to safe levels. The method we use is ultra violet (UV) light.

Treated water is then sent out to coastal outfalls:

- Moa Point (Wellington) out 1.8km ocean outfall into Cook Strait

- Seaview (Upper Hutt and Lower Hutt) is pumped to an outfall near Bluff Point

- Porirua outfall is near Rukutane Point

- Western (Karori) down a pipeline to the South Coast

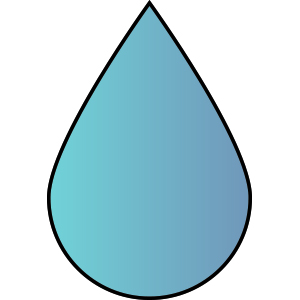

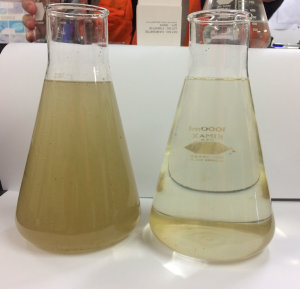

Here is an image of the influent [left] (the water that enters the wastewater treatment plant) and effluent [right] (the treated water as it leaves the treatment plant). These samples were taken from Moa Point wastewater treatment plant.

This influent sample was taken once the wastewater went through the milliscreens in the treatment process.

All wastewater treated at our treatment plants is treated to a high standard so that bathing guidelines in surrounding swimming bays around the ocean outfall are met.