Te Mārua Water Treatment Plant Capacity Upgrade

On behalf of Greater Wellington Regional Council, we are upgrading the Te Mārua water treatment plant to ensure reliable and healthy drinking water for the residents of the Greater Wellington Region.

If you have any questions about this work, please contact:

Wellington Water, 04 912 4400

Latest Updates

Excitement is building as, thanks to a lot of hard work, the process of final commissioning of the Dissolved Air Flotation plant (DAF) is underway.

It's been another month of great progress with steel platforms finished on the new DAF plant, a second CO2 tank put into service and more - check out the latest footage.

Check progress on site over the last month with our latest time lapse footage.

Works are underway on the component upgrades, on track for completion in July 2025.

Why are we doing this work?

The Te Mārua water treatment plant is a critical infrastructure asset to Wellington region. It currently provides up to 80 million litres of drinking water per day (MLD), at an average of 60 MLD - approximately 45% of the Wellington region’s 135 MLD drinking water demand.

The plant is designed for a maximum plant flow of 140 MLD, however is currently limited to 80MLD under specific raw (untreated) water conditions.

Recent population growth forecasts and water consumption data indicate that over the next two years the risk of water supply restrictions to customers could increase significantly.

We are optimising the treatment capacity of the Te Mārua plant to achieve the 140 MLD target of safe drinking water under projected, future raw water conditions.

These upgrades will allow the plant to provide a larger amount of water to meet the needs of the region, while also improving the plant’s ability to remove algae, sediment, and odour from the water.

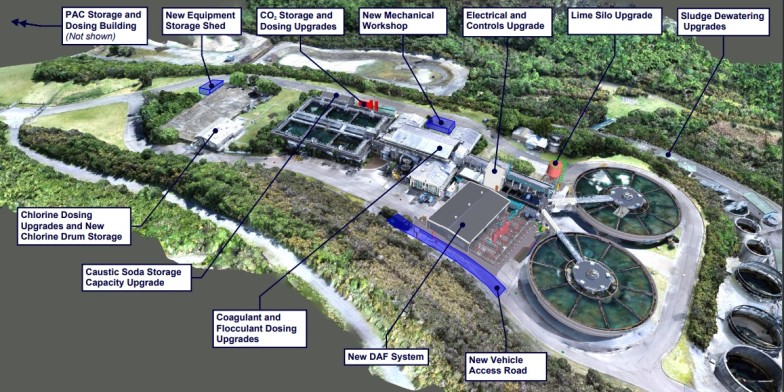

What does the upgrade involve?

A key part of the capacity upgrade is installing a Dissolved Air Flotation (DAF) plant. This technology involves using air bubble flotation to remove suspended solids, oils, and other contaminants from raw water. The DAF is manufactured by Canadian company AWC Process Solutions, a word-leader in these systems.

A key part of the capacity upgrade is installing a Dissolved Air Flotation (DAF) plant. This technology involves using air bubble flotation to remove suspended solids, oils, and other contaminants from raw water. The DAF is manufactured by Canadian company AWC Process Solutions, a word-leader in these systems.

Enabling works for the project kick off in February 2023 followed by a range of initial component upgrades including a new lime silo and CO2 tank.

Installing the DAF plant is expected to start late 2023 or early 2024 with the goal of commissioning the plant in October 2024.

The upgrades will be planned and executed without compromising drinking water supply and quality from the plant.

All Updates

Over the last few months our teams have been building up to the final stages of commissioning the DAF – a key part of the capacity upgrade. This technology involves using air bubble flotation to remove suspended solids, oils, and other contaminants from raw water.

The first stage was commissioned late last year, enabling the plant to treat and supply an additional 20 million litres of drinking water per day.

Preparing for the final stages has included constructing the roof canopy over the DAF's three 'trains', which will protect the skimmer and equipment.

DAF trains under new canopy

Chlorine dosing upgrades have also been completed with installing the new chlorine pipework and a fourth chlorine drum and associated pipework.

Chlorine dosing upgrades underway

Meanwhile the crew has been carrying out checks and tests of the DAF equipment, filling the chambers as part of pre-commissioning activities.

Then comes wet commissioning, a staged process which involves running and testing systems and testing water quality in each of the three 'trains'. This is followed by filtering the water and carrying out further tests to ensure positive water quality output.

Further processes will be followed to ensure the DAF is performing well and producing a high standard of water quality, before it is commissioned – filtering water into the network.

Once completed, the DAF will enable the plant to treat and deliver an additional 50 million litres of drinking water per day.

Crews have completed installing the steel platforms over the Dissolved Air Flotation plant (DAF) while work continues on the DAF wall structure along and installing mechanical and electrical systems in the pump and plant room.

Other core milestones over the last month include:

• Second CO2 tank commissioned and now in service.

• Structural remediation has been completed for Filter 1 and new nozzles and first media layers installed.

In the background there is also a lot of work going on with planning the commissioning of the upgrades and working with suppliers and the existing plant operators on handover, maintenance and operational documents.

Check out the activity here

Over the next few weeks. the crews will be very busy including completing the DAF wall structure, along with finishing installation of all steel platforms, canopies and continuing electrical installation in the pump and plant room. Filter 1 media installation will be completed and commissioning started.

Work is also underway on the 'dosing packages' which include upgrading the systems and equipment that are used to treat and clean the water. This includes coagulants that help tiny particles in the water stick together in little clumps, and flocculants that help these little clumps stick together even more forming large 'flocs'. These either sink to the bottom of a clarifier or stick to the air bubbles in the DAF and float to the surface as foam that can be scraped off and collected as DAF sludge.

After coagulated and flocculated particles are removed in a clarifier or DAF, clarified water is sent to the filters where the process of producing clean water is now significantly easier!

Dosing systems

It's steady as she goes on site with ongoing construction of the new Dissolved Air Flotation (DAF) plant - including finishing installing the inlet and outlet pipe system - which you can see in the time lapse video below.

Meanwhile the crew is hitting some milestones with other upgrades including:

- The second CO2 tank has been installed and will be commissioned by the end of August

- Filter 1 wall remediation is in progress and the new nozzles and media will be installed once remediation is complete

- Sludge dewatering centrifuges and conveyor have been commissioned and testing is complete

CO2 tank

DAF inlet/outlet pipe

Construction of the Dissolved Air Flotation plant DAF) wall structure is tracking to schedule along with fitting out the pump and plant room and installing the inlet and outlet pipework.

The DAF structure under construction

Check out time lapse footage showing progress on the DAF including the inlet and outlet pipes over the last month. DAF technology involves using air bubble flotation to remove suspended solids, oils, and other contaminants from raw water.

The structural steel that is critical to the completing part of the DAF commissioning process is also now being fabricated and the first steel platforms will arrive on site before the end of July. The team will start installing these structures during August.

Meanwhile among a range of other project milestones over the last month, the second CO2 tank has been installed and commissioning is underway.

The second CO2 tank now installed

The second sludge dewatering centrifuge control panel has also arrived on site and the sludge dewatering system is now commissioned and under a trial period.

Next month we expect to see commissioning of both the sludge dewatering and CO2 upgrade packages completed!

It has been another steady month of progress with ongoing work on the Dissolved Air Flotation tank wall structure - which is featured in the time lapse footage here

Progress in other key areas includes work fitting out the pump and plant room, completing the drainage pipework and starting work on refurbishment of filter 1 (image below showing the team water blasting the filter concrete structure ).

We are refurbishing all six filters to ensure they match the new capacity of the plant once upgrades are finished. The filters are concrete structures with a filter floor and 3mm slotted nozzles for filtration and backwashing. Each filter currently contains five layers of media: coarse gravel, fine gravel, coarse sand, fine sand, and Granular Activated Carbon (GAC).

Work started 4 June on filter 1 and the plan is to complete the next two filters in 2025 and the final three in 2026. The refurbishment involves

- Vacuuming out the existing media layers

- Removing all nozzles and installing new ones

- Water blasting the concrete structure

- Cleaning the laterals

- Inspecting the filter tank

- Adding new, regraded layers of coarse gravel, fine gravel, sand, garnet, and GAC.

Over the last month we've made great progress on the tank wall structure for the new Dissolved Air Flotation (DAF) plant - a key part of the capacity upgrade that will add 60 million litres of drinking water per day to the water treatment plant's capacity.

Plenty of other activities have been underway too including fitting the inlet and outlet pipes that will connect the existing plant and the new DAF, installing both centrifuges ( a device used to separate components from a mixture) for the sludge dewatering system and planning for the installation of the second CO₂ bulk storage vessel.

View a snapshot of progress over the last month, focusing on DAF wall construction in the latest time lapse footage

In this time lapse footage you can see great progress being made building the new DAF over April.

DAF technology involves using air bubble flotation to remove suspended solids, oils, and other contaminants from raw water.

The DAF will be commissioned (put into operation) in three stages, each adding adding 20 million litres of drinking water per day to the water treatment plant's capacity. The team is on track to commissioning the first stage in November this year,

There is plenty of progress in other areas of the upgrade including completing the new lime silo generator and finishing work converting the flouride room into a mechanical workshop.

Great progress is also being made on the new sludge dewatering package. The upgrades is this package will allow the system to handle the additional sludge resulting from the DAF system. Currently the team are ion track to commissioning the new package in June this year.

In fact, the team have been able to improve sludge dewatering efficiency, reducing the amount of sludge being produced, thus

sending less tonnage to landfill. As landfill costs continue to rise across the region this is a great outcome for budgets and a great environmental win as well.

We've continued to make great progress over the Summer as we head towards completion in May 2025.

Some key milestones include construction now well underway on the new Dissolved Air Flotation (DAF) plant. Check out the time lapse footage of work during February showing construction of the wall structures.

The new caustic soda tank has been installed and improvements to the storage room are being completed.

We're also pleased with progress being made on sludge dewatering upgrades that will allow the system to handle the additional sludge resulting from the DAF system. To make the upgrades possible the team have installed a temporary sludge dewatering system allowing the old system to be decommissioned. The new system scheduled to be commissioned and operational in June 2024.

Meanwhile during March, the team will be focused on continuing work to reinforce the walls of the DAF and planning for its commissioning.

We are also expecting to complete the lime silo generator exhaust works during March and commission the caustic soda tank.

- We’ve installed and commissioned the replacement CO2 dosing system and bulk storage tank, this system is now in service.

- The lime silo has been installed on its foundations and will be commissioned later this year.

- Following the completion of service relocations, the excavation for the new Dissolved Air Flotation (DAF) building are nearly complete. The DAF is the primary focus of the project, and when combined with the other system upgrades onsite, will increase the water treatment plant’s capacity by up to 60 ML/d.

These upgrades will increase the treatment capacity of the plant to meet the growing needs of the region, while also improving the plant’s ability to remove algae, sediment, and odour from the water.

We look forward to providing another update soon on this exciting project.

Good progress is being made on the new lime silo and the new CO2 dosing system storage tank.

Later this year, we’re set to start constructing the foundations for a new dissolved air floatation (DAF) unit to increase the output capacity.

Major enabling works are now underway for the Te Mārua water treatment plant upgrade.

Since February, the focus has been on completing initial works.

Today, we kicked off works to enable major component upgrades with piling for the pad that will eventually hold the new carbon dioxide storage tank.

The piling works will continue for the next week . Then we’ll be ready to commence the piling for the lime silo pad.